Jul 08,2024

Precautions for the use of hydraulic pump

1. When the hydraulic pump is started, it should be moved several times. After the oil flow direction and sound are normal, it should be operated under low pressure for 5~10min, and then put into normal operation. Before the plunger pump is started, the pump must be filled with clean working oil through the drain on the shell.

Jan 15,2024

Composition and function of hydraulic pump

Hydraulic pump is a device that converts mechanical energy into hydraulic energy and is widely used in various industrial fields. This article will be described from the composition and function of the hydraulic pump.

Jan 15,2024

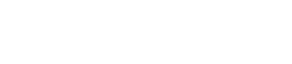

The main application range of hydraulic pump

Hydraulic pumps are used in industrial hydraulic machines. These are used in cranes, excavators, loaders, vacuum trucks, tractors, forestry equipment, dump trucks, graders, mining machinery, etc.

Jan 15,2024

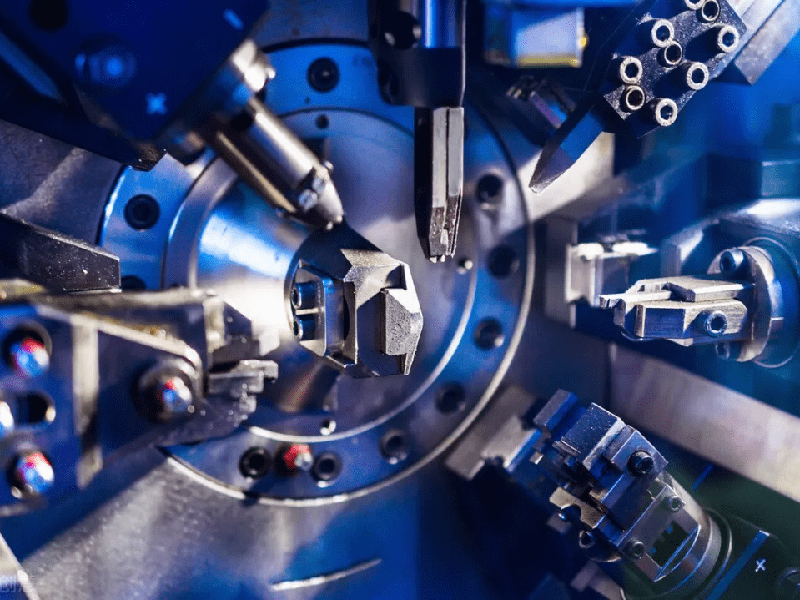

Difference between hydraulic pump and motor

The hydraulic pump is an indispensable part of the hydraulic system. It uses the mechanical energy of the engine to convert it into fluid energy. Hydraulic systems are primarily designed to transmit power in a controlled manner through pressurized fluid. In a hydraulic system, pressure is generated by the design of the applied force and the size of the pipe. The smaller pipes in these systems increase pressure and resistance.

Jan 15,2024

Maintenance of hydraulic components

1 Professionals are important. Debugging and maintenance of hydraulic equipment requires professionals to carry out.

Jan 15,2024

Precautions for hydraulic components

According to the pressure and use of occasions to choose the tubing, tubing must have sufficient strength, the inner wall should be smooth, clean, no sand, no rust, no oxide skin, for long-term storage of the pipe, before processing should be pickling, cleaning, flushing, and inspection.

Jan 15,2024

What are the types of hydraulic pumps?

1, according to whether the flow can be adjusted can be divided into: variable pump and quantitative pump. The output flow can be adjusted according to the needs of the variable pump, the flow can not be adjusted called quantitative pump.

Jan 15,2024

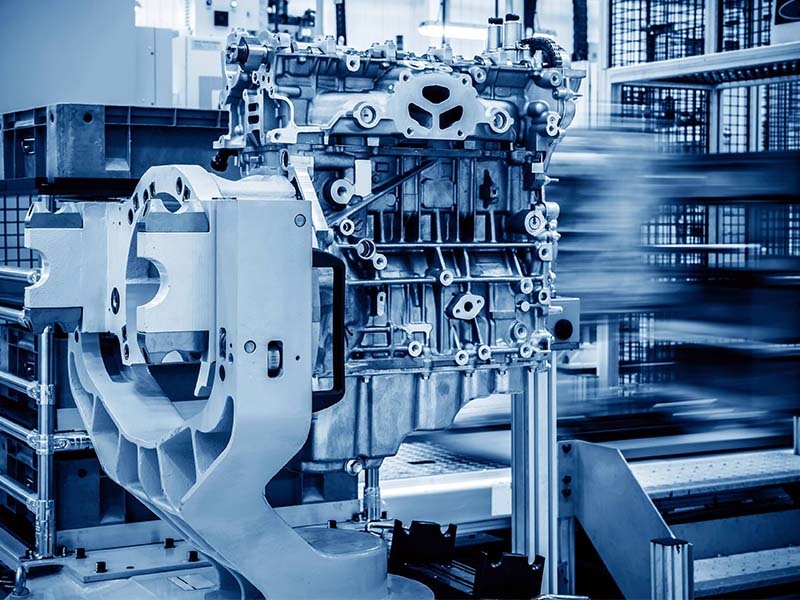

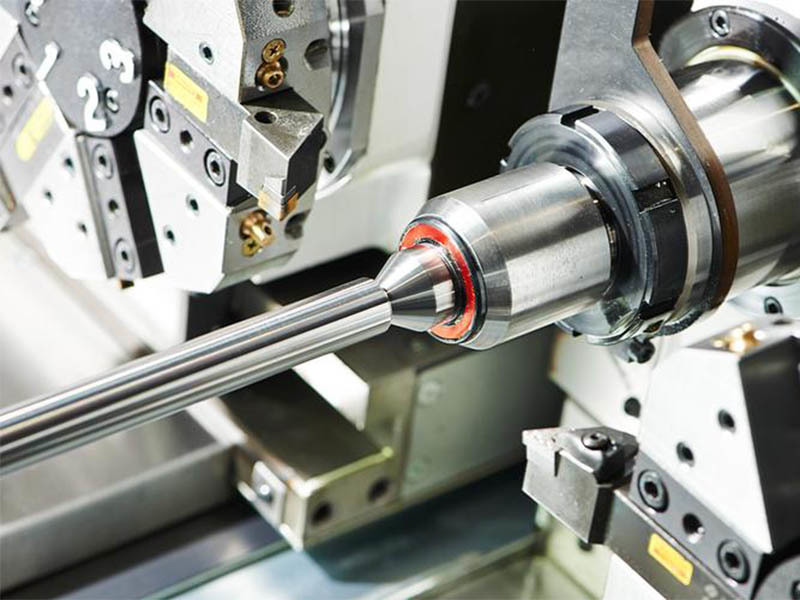

The working principle of plunger pump

The working principle of the plunger pump: The plunger pump relies on the reciprocating movement of the plunger in the cylinder to change the volume of the sealed working cavity to achieve oil suction and pressure. When the plunger pump is working, under the action of the cam on the camshaft of the fuel injection pump and the plunger spring, the plunger is forced to reciprocate up and down to complete the task of pumping oil.

Jan 15,2024

What is included in a complete hydraulic system?

A complete hydraulic system consists of five parts, namely, power components, the implementation of components, control components, auxiliary components and hydraulic medium. The function of the power element is to convert the mechanical energy of the prime mover into the pressure energy of the liquid, which refers to the oil pump in the hydraulic system, which provides power to the entire hydraulic system.